Manufacturing Process At Sarfraz Overseas

To keep manufacturing process efficient, we have adopted procedures to follow that help us to maintain the speed of product manufacturing, material selection, quality check and labor safety.

Here we will elaborate the process that is followed to develop a sports equipment.

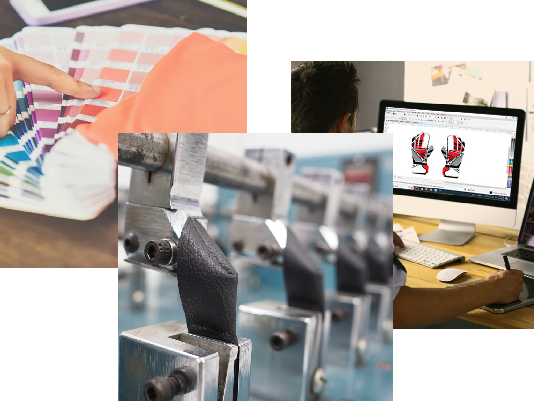

First step is to analyze the product requirement i.e product specification. Our professional pattern masters and RAD (research and development) team discuss all the aspect of the product such as measurements, materials characteristics, product usage, product life and product safety aspects (if a product falls in PPE) (Personal Protection Equipment). After discussing a product, next step is to develop a digital prototype of the product, where the picture becomes clearer of all the details in product and that prototype is sent to customer to get his opinion. After the approval of the digital prototype, a physical sample of the product is made to compare it to the original transcript of specifications provided by the customer. When a product meets all the aspects mention to specification sheet, that physical sample is shipped to the customer. After his approval, we move forward to the mass production of the product.

Product Pattern

We have a team of professional pattern masters who have vast experience in their product line and have experience working with major brands of the world. Their experience and expertise has helped Sarfraz Overseas to gain a prominent position among major sports equipment manufacturers around the globe.

Synthetic Materials

In different sports equipment, different synthetic materials are used. For instance, in boxing gloves, traditionally preferred material used to be Leather. But since the introduction of faux leather of synthetic leather, original leather has been replaced by synthetic leather almost 70%. When we are selecting synthetic materials that are used in our sports equipment, we always try to select a synthetic material that is produced considering the environment and recyclability.

Fabric Selection

During the course of fabric selection, we carefully examine the GSM of the fabric and properties of that fabric, such as percentage of cotton, polyester, nylon etc. Some products require specific fabric materials, and importantly, products that are used as heat- and flame-resistant, such as motorbike pants etc. Nomex® and Kevlar® fiber fabrics are used.

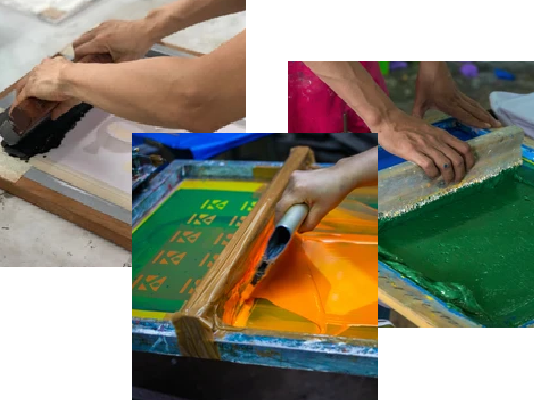

Screen Printing

Screen printing or silk screen printing is a traditional way of printing logos and designs on sports equipment. At Sarfraz Overseas, there is a dedicated department for screen printing. We consider it important that the inks that we use for screen printing are environmentally friendly and are bleed-free.

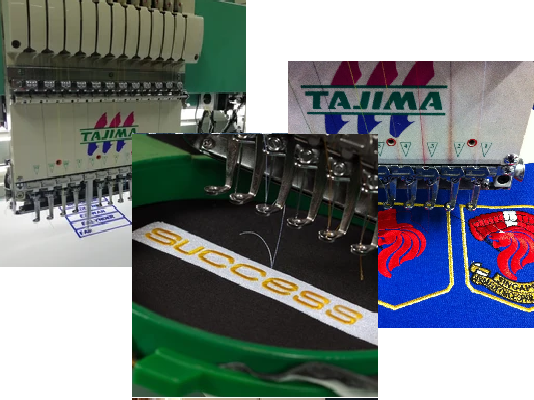

Heat Transfer Printing

We have capability to print fabrics, such as sports apparels, t-shirts etc, with DTF stickers, Screen-printedScreen-printed heat transfer stickers, Stone heat transfer stickers and leather with vinyl stickers.

Product Packing

We produce and pack our manufactured equipment accordingly to the requirements of clients. Custom packing solutions are provided. Our experienced graphic designers are always ready to help clients to make their products presentation impactful.